SOLAR BOLLARD LIGHTING THE WAY TO A SUSTAINABLE FUTURE

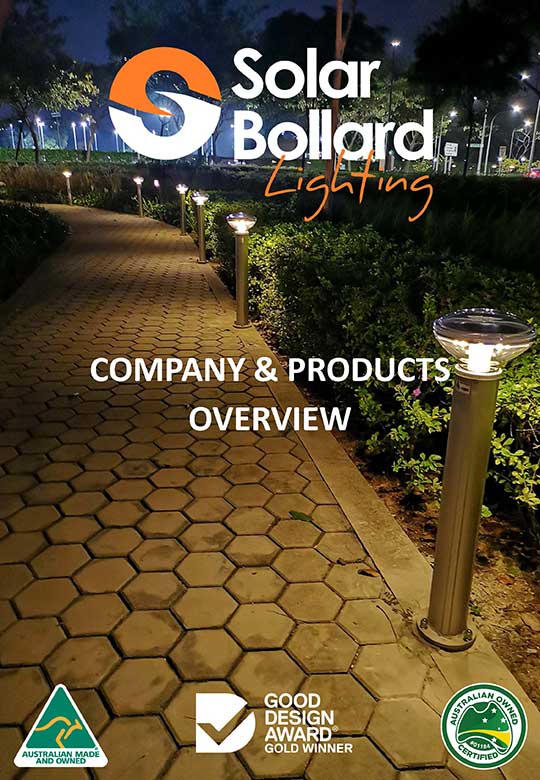

Solar Bollard Lighting® (SBL) an Australian lighting firm, was the first to innovate and bring to market the world’s first ever integrated all-in-one solar light over twenty years ago. As the leading solar bollard light manufacturer globally, we have continued to pioneer more world first original designs that offer even more fit-for-purpose and sustainable solar lighting solutions.

Key Wholesalers Pty Ltd is an Australian company who pioneered and commercialised the world first integrated all-in-one solar light two decades ago, well before solar lighting became credible and climate change became a mainstream issue.

In 2013, the company rebranded as Solar Bollard Lighting® (SBL) and focused on one solar lighting technology. Solar Bollard Lighting has established itself as the global leader in solar lighting, with its high-quality and durable products that can withstand the toughest conditions, and in doing so became the world’s No.1 solar lighting manufacturer.

Many first-to-market innovative milestones have been achieved due to our sustainable and purpose-built designs, such as

- World first All-in-One solar bollard light commercialised in 2005

- World first Fall Safe Design solar bollard light

- World first IK10 vandal-resistant solar bollard light

- World first IP68 submersible solar bollard light

- World first stand-alone solar light that operates in full shade

With more than 40,000 solar bollard lights installed in commercial projects across 40+ countries, our Australian Made solar bollard light is market proven within some of the harshest environments the world has on offer already. Why we offer a 10-year warranty.

Our market proven history guarantees our clients, we only deliver the highest quality solar bollard lights, with a durable design that will outlast all our competitors, is the better value proposition long term, and ensures a great outcome for the environment.

The SBL2 Series is the superior lighting solution for

- Government sector public spaces

- Defense & embassies

- Mining, gas & oil industries

- Marine applications

- Education & faith facilities

- Commercial infrastructure

- Residential, retirement & aged care

- Sport, recreation & theme parks

- Hotels & resorts.

Here is an example comparison.

Other SBL key milestone, include:

- First Australian Made (AMCL Licensee ID number: 7739) solar lighting manufacturer.

- First Australian ISO 9001 certified solar lighting manufacturer.

POLICIES

QUALITY

ENVIRONMENT

SOCIAL

RISK

WHS

Solar Bollard Lighting® products and business are built around four core principles:

- Australian Made by an Australian owned company,

- locally sourced Australian component suppliers,

- minimal environmental footprint with a sustainable future

- power used within our own facility to create our product is 100% Green Power.

The 6106 T6 grade aluminium poles we manufacturer here in Australia are extruded and not casted with a mix of low-grade alloys. This ensures our bollard poles will achieve up to 30 years operational life and upgrading of only the solar light head only at end of life with another Solar Bollard Lighting product. All our product components are 100% recyclable.

Competitor products require at least two (2) – three (3) complete product change overs and reinstalls to one (1) SBL2 Series solar light head change over in a single 10-year life cycle. Solar Bollard Lighting products reduce future capital expenditure, and excessive waste.

Geographic Location and Shade Assessment

Some installation locations may have only two or three hours of sunlight a day or are situated under a fully shaded canopy of trees with no direct sunlight.

Every installation location has its own unique lighting dynamics, so when designing our SBL2 Series standalone solar bollard light, we wanted to push the innovation curve further, to offer a product range that would ensure continuous full illumination throughout the night, every night in more locations than ever before.

To ensure a long-life cycle and fit for purpose lighting outcome, we complete an initial geographical location and shade assessment for each project based upon the winter solstice profile for the exact location of installation before any product is dispatched.

This snapshot of the geographical location considers:

- The longest winter night that requires illumination.

- The shortest daylight hours for battery recharging.

- Additional disruption of peak sunlight due to:

- the low-tracking sun when shadows are longest

- historical averages of expected snow fall

- historical averages of winter rainfall.

Our power in = power out protocol assessment identifies what the current use will be, and the daily requirement to replenish the battery fully, based on the collected data for that location. The clients order can then be custom made to suit the exact project and provide a fit for purpose, long life cycle, sustainable procurement outcome.

We are not an off the shelf or mass production solar bollard light manufacturer with only one product line design, unlike our competitors who promote the same product globally, and claim it suits all geographic locations, levels of shading, seasonal snowfall, and winter rain. Laws of physics say it differently.

The following examples highlight the operational variance between different geographical locations based on full sunlight without any shade, seasonal snowfall or monsoonal rain being included:

Singapore is close to the equator with plentiful amounts of sunshine

- Nightly run times of each light differ by 0.08 hours between summer and winter.

- Peak sun hours (PSH) for recharge differ by 1.13 hours.

Edmonton, Alberta, Canada is much further from the equator, and it snows

- Nightly run times of each light differ by 9.75 hours between summer and winter.

- Peak sun hours (PSH) for recharge differ by 5.18 hours.

DOCUMENTS

ABOUT SBL

SBL SERIES S MODEL

SBL2 SERIES RANGE

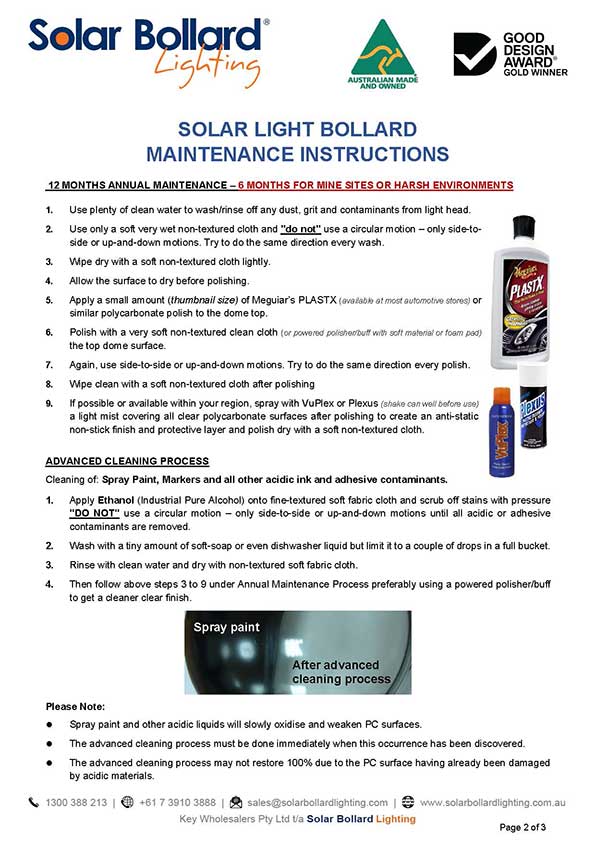

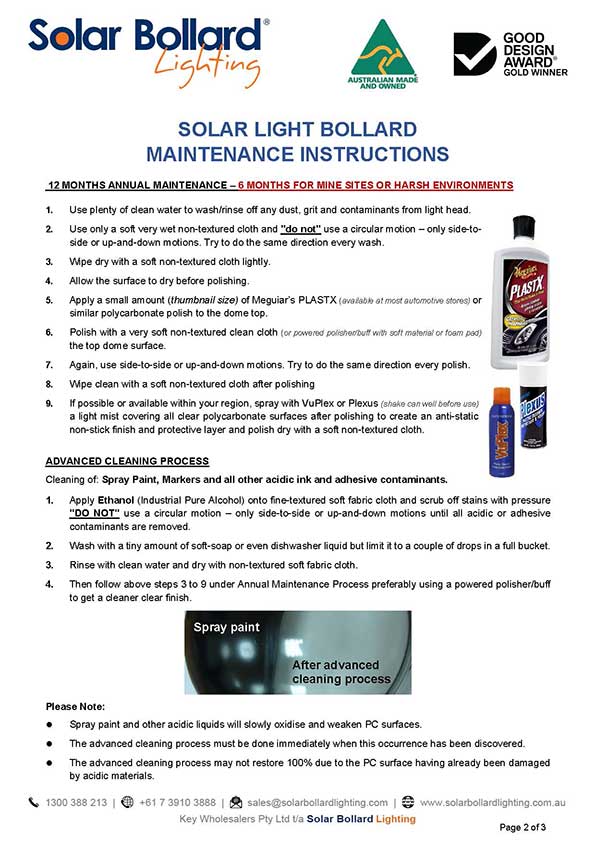

Maintenance Instructions

SYSTEM AUTONOMY

REAL BATTERY AUTONOMY VS RAINY DAYS -

Defined as the time the load can be met with the battery alone, without solar inputs, starting from a fully charged battery discharged to a maximum of 80%.

BATTERY OVER CYCLING

Battery discharge exceeds 80% of its fully charged capacity in one cycle (single day).

Over cycling the battery to a very low average state of charge during the year damages the battery and reduces its cycle life.

Fit for purpose batteries in solar lighting installations will provide a 10-year design life and at least 4.5 days autonomy based on the probability of the number of consecutive days with low solar irradiation.

A battery with sufficient capacity provides contingency and reliability in the worst conditions.

BATTERY

Lithium iron phosphate (LiFePO4) battery, also called LFP battery (lithium ferro phosphate), is the only power source of choice.

LiFePO4 batteries can typically operate within -20°C to 60°C (-4°F to 140°F).

We tested our single cylindrical cell (used as our storage battery) under laboratory conditions, cycling at the highest discharge and recharge currents to find the subzero temperature our cell would no longer operate:

- This point was at -35°C (-22°F).

Benefits of SBL using a single cylindrical 3.2V LiFePO4 cell

- Cylindrical cells are more reliable.

- The electrodes in a cylindrical cell are wound tightly and enclosed in a metal casing so can handle high internal pressures without deforming.

- Cylindrical cells radiate heat and control temperature more easily than prismatic cells, or multiple interconnected cylindrical cells, packed together to increase voltage or amperage.

- More kilowatt hours per cell – more than 4,000 cycles or 10+ years of continuous charging based on 30% maximum daily depth of discharge at low current rates.

- High energy to size and weight and much faster charging.

- Wide range of operating temperatures (-20°C - 75°C), high temperature resistance, hot peaks up to 350°C to 500°C.

- Safety - LiFePO4 batteries will not catch fire or explode.

- Environmentally-friendly - uses non-toxic materials (in line with SGS certification), non-polluting (in line with European RoHS).

Disadvantages of using multiple cells use by competitor products

When connecting multiple cells together:

- Mechanical vibrations, thermal cycling from charging and discharging, and mechanical expansion can separate the cell connections, and cause a circuit break.

- Balancing individual cells to ensure they recharge evenly.

Prismatic cell disadvantages - other competitors

- Prismatic cells are made up of many positive and negative electrodes sandwiched together, increasing the possibility for short circuit and inconsistency.

- Internal electrodes can easily expand and contract, causing deformation. This can lead to an internal short circuit and swelling, like lead batteries.

Charging below 0°C / 32°F

Some competitor manufacturers claim their LiFePO4 battery will operate between -40°C and 60°C.

- -40°C is not possible and is misleading.

LiFePO4 batteries can typically operate within -20°C to 60°C (-4°F to 140°F).

When attempting to charge a Lithium-ion battery below 0°C / 32°F (freezing) at an inappropriate charge and discharge rate:

- A chemical reaction (lithium plating) occurs, caused by the charge current forcing the lithium ions to move at a faster reaction rate than usual and accumulate on the surface of the anode.

- Less lithium is available to allow the flow of electricity and the battery’s capacity drops.

- The battery becomes less mechanically stable and more prone to sudden failure.

- This chemical reaction results in an increase of the battery’s internal resistance, which can have major consequences when linked in series or parallel connections.

- It reduces the rate of the chemical metabolism and causes a permanent reduction of the battery’s capacity. This will continue to reduce each time this reaction occurs.

![]() 1300 388 213

1300 388 213

![]() Intl +61 7 3910 3888

Intl +61 7 3910 3888

![]() sales@solarbollardlighting.com

sales@solarbollardlighting.com